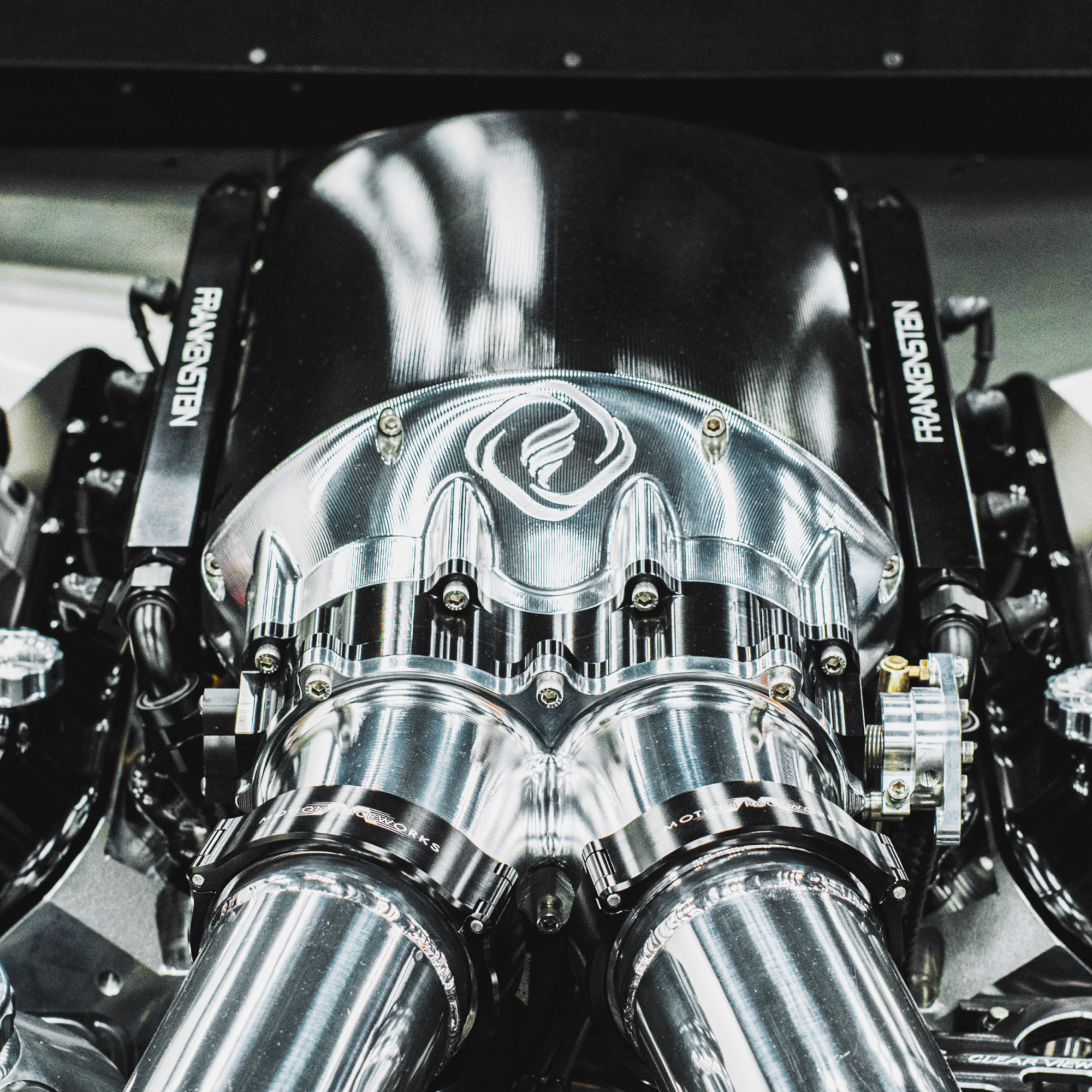

Frankenstein Engine Dynamics set out to do something bold—redefine the LS platform by building the most powerful LS cylinder head ever made. But power alone wasn’t the goal. We wanted more efficiency, less port turbulence, and a valvetrain so stable it’s practically meditative—even at 10,000 RPM. To achieve that, everything had to change. And it did.

A Clean Slate with No Compromises

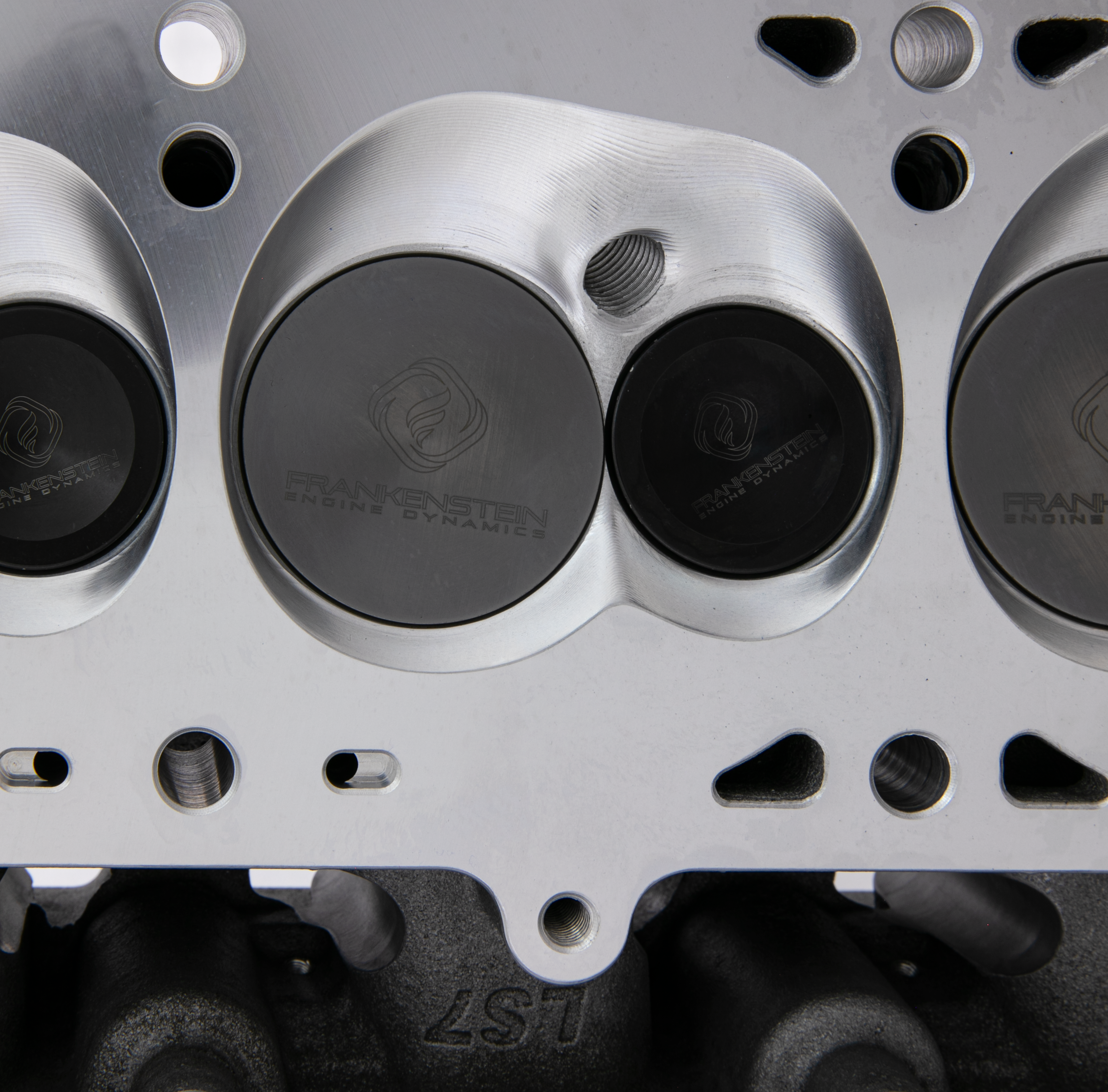

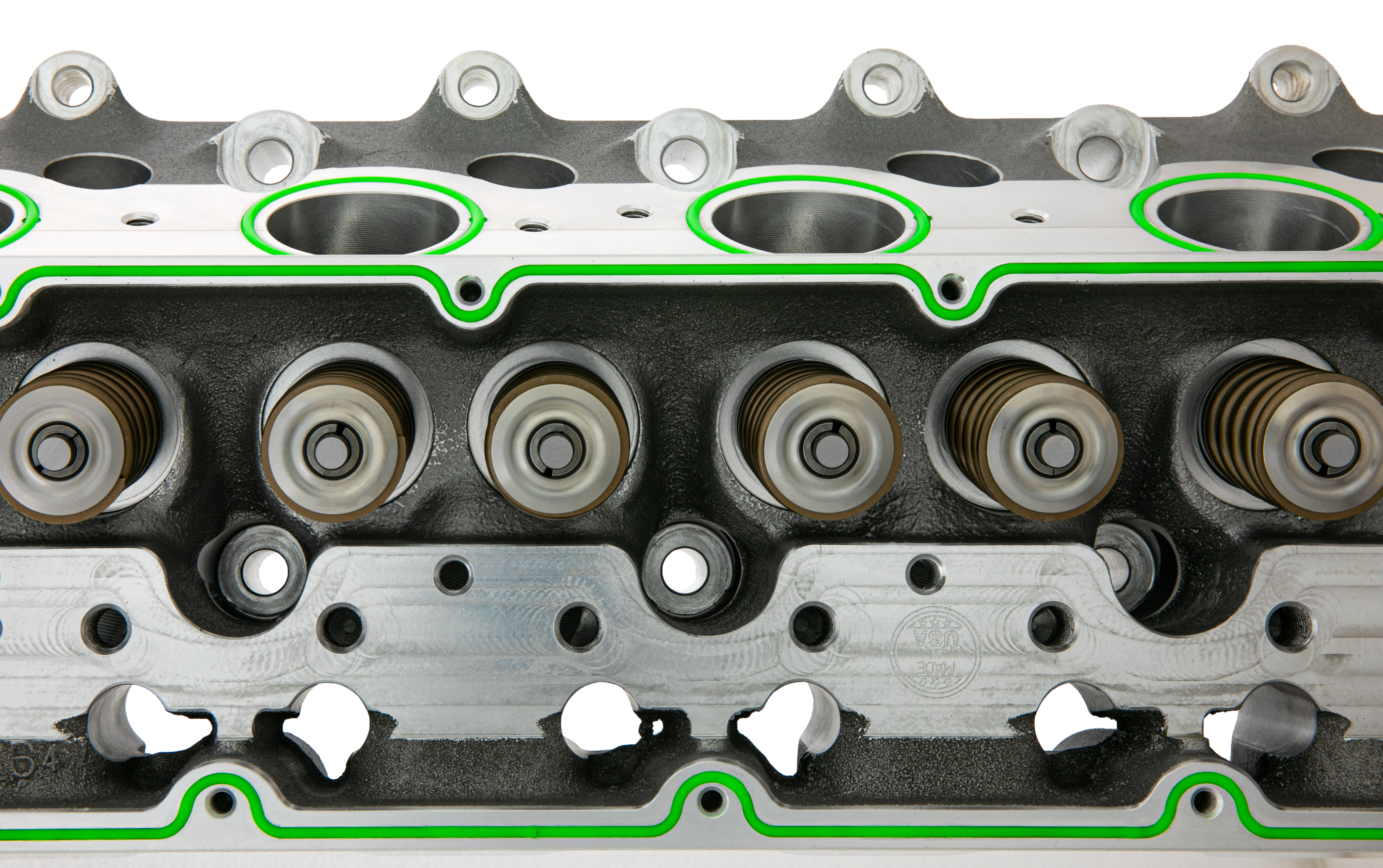

The journey started back in 2016, when Chris Frank, Brad Hall, and Jesse Meagher recognized a truth few wanted to admit: existing LS castings were holding us back. They had potential—but not enough. It was time to create something better from the ground up. We developed our own casting with raised runners, 10° and 15° valve angle options, and a valvetrain built to handle the most brutal racing conditions.

F-Series Debuts: Quiet Confidence

We unveiled the F-Series at PRI 2018. It was unlike anything the industry had seen—a raised runner LS cylinder head packed with innovations. At first, the response was muted. But then the dyno results started rolling in. Numbers that didn’t make sense… until people started asking what was inside.

Throwing Out the Rulebook

OEM LS castings are good—but we weren’t interested in "good." We wanted great. That meant ditching conventional thinking and throwing the baby out with the bathwater. We didn’t tweak—we rebuilt.

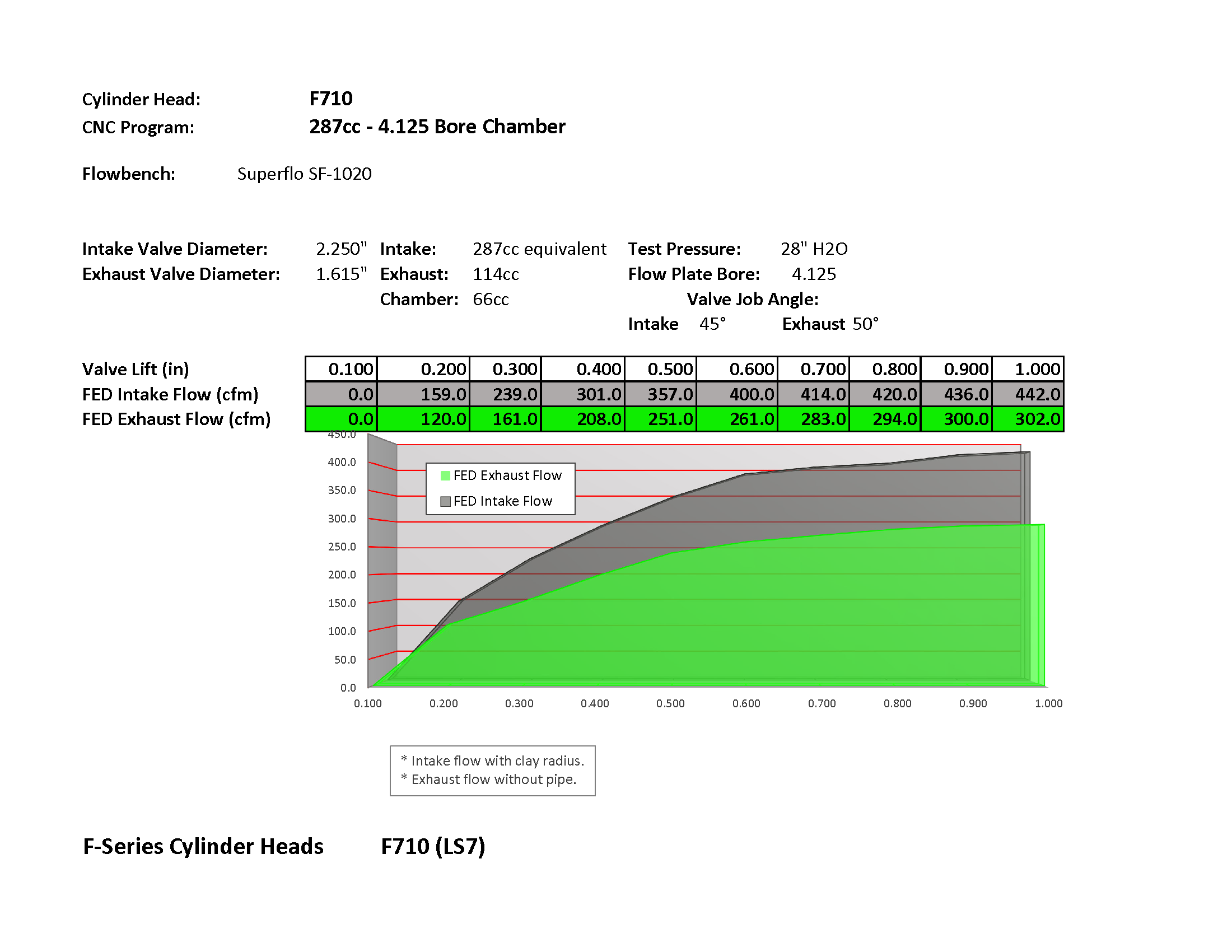

Building from a clean slate gave us freedom, but it came with responsibility. We had to maintain OEM compatibility where it mattered, without sacrificing performance. The design philosophy was holistic: don’t just focus on the head—optimize the whole system. Every part had to work in harmony to make real, usable horsepower—not just flowbench numbers.

Beyond the Flow Bench

Cylinder head development has changed dramatically over the past 50 years. Flow bench CFM might still be a headline number, but it doesn’t win races. Airflow alone doesn’t equal horsepower.

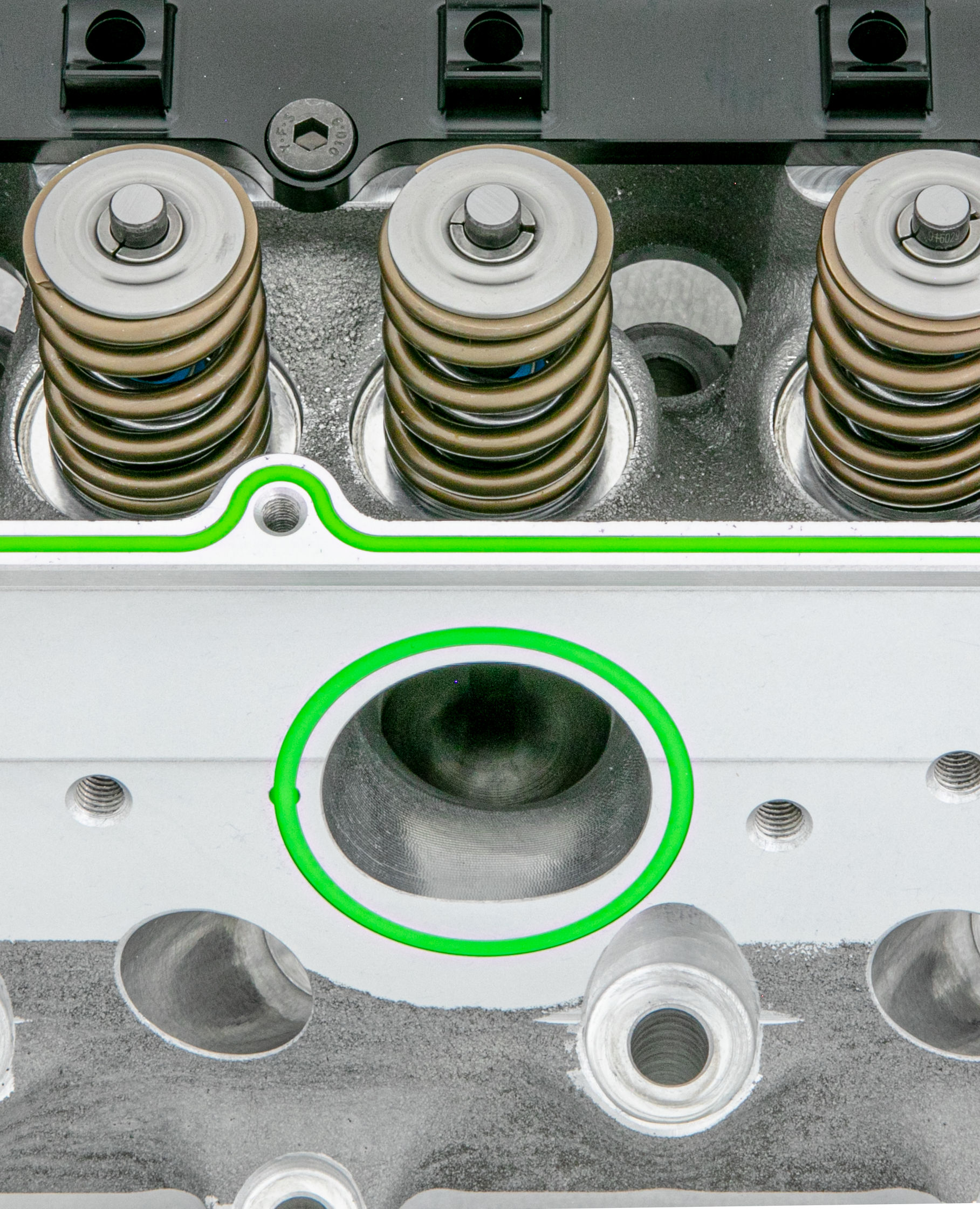

That’s why we use Reactive Airflow Modeling—our proprietary process that simulates real-world dynamics of the entire induction system. It factors in air speed, pressure, turbulence, recovery, combustion behavior, and how fuel and air interact across the rev range. It's a performance-first approach that sees the whole picture, not just a single data point.

Built to Break Limits

We engineered the F-Series to push the envelope so far, even existing aftermarket components couldn’t keep up. So we partnered with industry leaders like PAC Racing Springs and Jesel to develop parts capable of matching our demands. Once we had confidence in the valvetrain, we let the airflow loose.

We started with .250" raised intake runners and .200" raised exhaust ports. This offered a more direct path for airflow—but we didn’t stop there. We repositioned the valves and shifted the pushrod to clear space, reduce interference, and improve rocker alignment. That pushrod bulge you see? It’s there for a reason: better flow.

The exhaust ports were moved in-line with the header flange to clean up exhaust evacuation, while the spark plug was relocated to the center of the chamber for a cleaner, more complete burn. And to keep things compatible, we extended the intake flange to fit most popular aftermarket and OEM manifolds.

The Result? Unmatched.

The F-Series delivers something rare: high RPM capability and early peak torque. It breathes harder, faster, and more efficiently than anything else out there. With improved volumetric efficiency, less ignition timing is required to hit peak power—and tuning becomes both easier and more precise.

This is more than a cylinder head. It’s the culmination of years of obsession, testing, and engineering without limits.