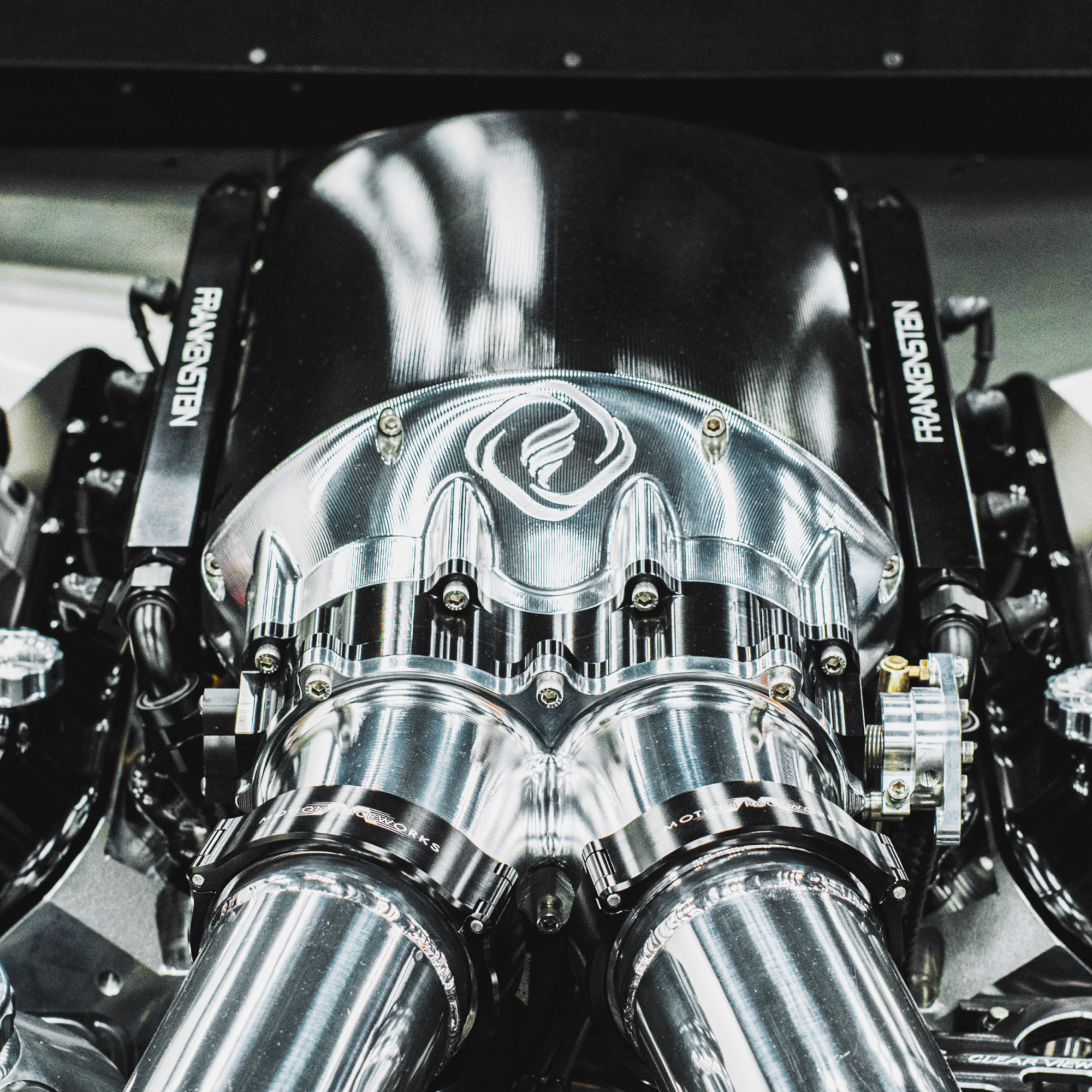

Frankenstein cylinder heads generate more power because we synchronize the performance characteristics of the intake port, combustion chamber and exhaust port. FED port programs meet a myriad of proprietary performance measures to meet high standards for throttle response, volumetric efficiency and absolute combustion efficiency. While we currently still share Flow Bench numbers, they are not a complete reflection of performance. We’re not hating on the Flow Bench, in fact we have two in our shop. But today’s advanced porting methods have come a long way since the 1970’s when Flow Bench numbers first became groovy.

A Perfect Intake Port

Cylinder head intake port geometry, taper and shape are refined by cnc machine to enable high velocity flow. Each cylinder head casting has inherent design characteristics based on its application. The casting type determines the port program, which is developed and refined by Frankenstein to generate optimal airflow. The cnc port program ensures ideal airflow based on the following: runner length, volume, guide placement, valve angle and valve location relative to the chamber. Intake port designs also factor valve job type, chamber shape, plug placement, cam lift and engine displacement. Frankenstein’s cylinder head intake ports generate high flow and high in-cylinder flow motion of the air-fuel mixture as it enters the combustion chamber. High velocity of flow compacts or “supercharges” the air-fuel charge in the chamber while generating extreme turbulence, which is the ideal condition for rapid ignition and combustion

A Gloriously Powerful Exhaust Port

Cylinder head exhaust porting is a critical aspect of cylinder head porting, and Frankenstein leverages this key performance factor others overlook. Advanced cylinder head porting optimizes exhaust port performance characteristics relative to intake port flow and the combustion chamber’s accelerated combustion capability. Frankenstein exhaust port designs revolve around optimizing the overall port shape, which accounts for guide boss geometry, casting style, runner length and orientation, chamber size, intake velocity, pressures and engine performance targets in addition to power adder type. Each FED exhaust port cross section is precisely machined to ensure exit velocity is consistent across the cross-sectional area of the port

A Violent Combustion Chamber

Why does advanced cylinder head porting make so much more horsepower? The answer in a nutshell: rapid combustion. Due to FED’s systemic approach to intake and exhaust porting, the combustion chambers see higher kinetic turbulence and ram charging which generates peak ignition speed and an accelerated burn rate. The effective outcome is maximum horsepower capability in naturally aspirated engines and exponentially higher performance with power adders.

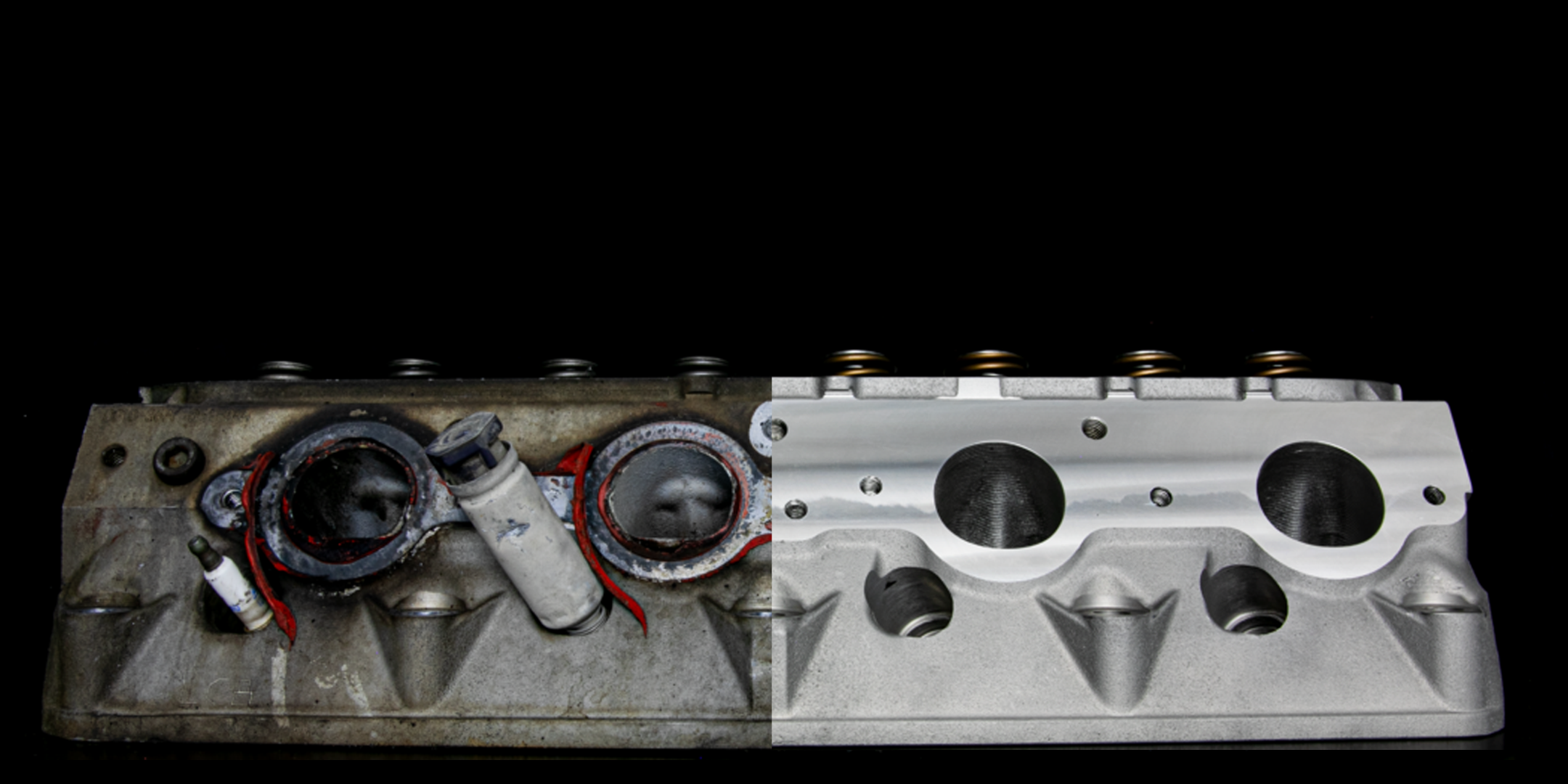

Our Top Secret Valve Job

The valve job is under-rated by most but at Frankenstein it is a key element to our legendary performance. The valve is certainly the most perplexing impediment to air flowing through a cylinder head and it’s only appreciated by those of us who spent years testing valve jobs on tracks and drag strips. The gains achieved by a proper valve job can’t be understated, particularly in high horsepower applications, as it’s possibly the most complex and critical design element every form of performance racing. In fact, it is one of many competitive factors used by professional race teams, who customize valve jobs to tune the throttle response to their driver’s preferences.

A valve job does much more than ensure mating surfaces of the valves and seats control air entering and exiting the combustion chamber. It’s more than perfectly concentric cuts and angles for the seat, top and bottom angles. Fundamentally, the valve job influences air flowing into the cylinder, how it enters, where it follows surfaces and when air becomes most turbulent in the cylinder. It encompasses the casting style, the throat shape, valve shape, angle and size, lift, air velocity and many other application factors. The outcome is clear to us at Frankenstein and it is how we can hold such high internal performance standards for each type of cylinder head we service. Explaining FED’s advanced porting services is a challenge but we’ll settle for how our customers and on-line forums put it, ‘I don’t know how FED does it, but they just crush everyone else’.

Frankenstein’s advanced cylinder head porting steps:

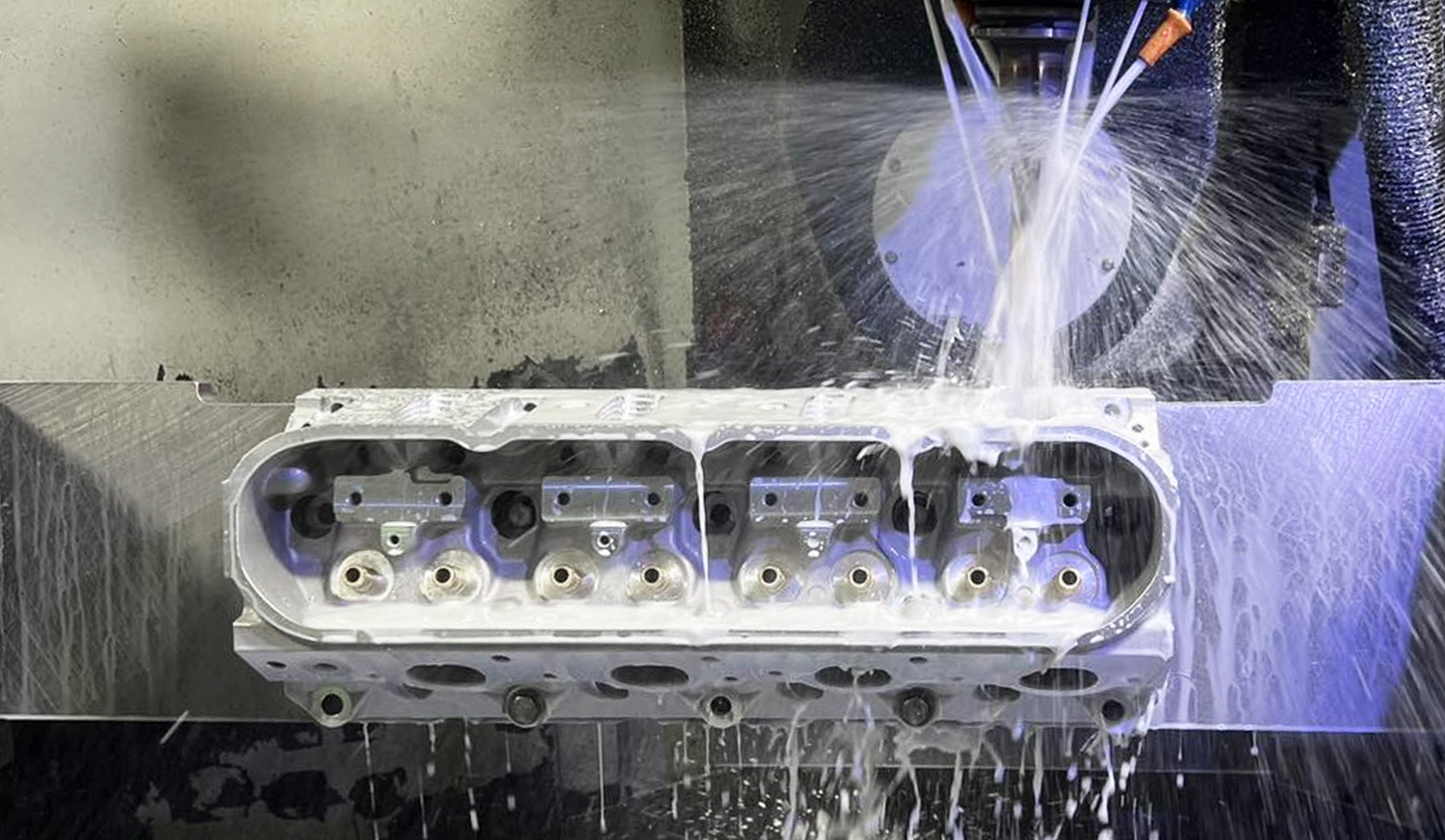

- Complete teardown, cleaning and inspection.

- FED’s high performance porting via 5-axis CNC to synchronize and optimize intake and exhaust port performance characteristics in conjunction with combustion chamber optimizing. (some casting chambers don’t apply)

- Pressure testing for leak detection.

- Precision Newen CNC valve job which ensures near zero runout.

- All sealing surfaces and ends are PCD machined true.

- Meticulous hand blending and deburr.

- PCD surfacing optimal for modern MLS head gaskets.

- Final wash and assembly to strict tolerances.

- Extreme attention to detail and quality at every stage.